Machining has always been about precision and speed. But in the extremely competitive field of manufacturing efficiency has become an essential requirement. When you’re manufacturing automotive parts, aerospace components, or high-tech electronic components, the tools that you select directly impact your profitability. Drills that can be indexable, high-speed drills, tungsten carbide-based end mills, and threading insert are making a serious impact.

This isn’t just an update to the old tools. These tools offer a better way to work, as they can reduce the time spent in downtime and expenses while delivering superior results. We’ll explore the ways they can assist companies cut faster, drill more efficiently and finish more quickly.

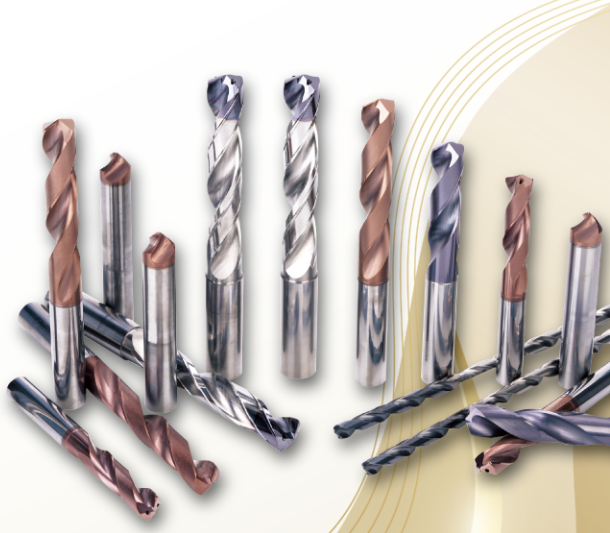

Image credit: stwang-tw.com

Indexable Drills: More Holes, Less Hassle

Drilling large holes used to be costly and time consuming. The drills were prone to wear out required sharpening and often slow production lines. This is why more and more machinists have switched to indexable drills. If the tool gets dull, instead of replacing the whole tool just change the cutting inserts.

What makes indexable drills distinctive is their efficacy. These drills are engineered to provide heavy-duty performance and extended runs. They also require little maintenance. With replaceable inserts, you reduce the amount of waste, decrease tool inventory, and allow machines to run longer. SHANG TZANG WANG ENTERPRISE, CO., LTD offers disposable core-stays that provide reliable performance for large-diameter applications. This upgrade is suitable for shops that carry out regular hole-machining. It can save them the time and effort they spend each week.

High Speed Drills: Built to meet the demands of today.

In an setting where speed is essential high-speed drills enable you to complete the task quickly without sacrificing accuracy. They are perfect for tough materials and quick cycles. From precision medical equipment to high-volume automotive parts They are used in every industry.

Modern high-speed drills are equipped with designed flutes that are optimized and cutting-edge coatings that prevent heat buildup, reduce friction and increase the life of the tool. This means less breakage and less tool replacements and a larger number of components. If you’ve ever had to deal with a broken drill during your process switching to high-speed drills could be a great experience.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

When it comes to milling, tungsten carbide end mills are the workhorses of the shop floor. The end mills’ durability and heat resistance make them a top choice for cutting through tough materials. Whether you’re roughing out large sections or finishing edges, these machines give steady results that the operators can trust.

The variety of tungsten carbide is what makes them so special. The different coatings, angles, and flute count can be customized for a wide variety of jobs, from aluminum to titanium. Endmills made of carbide are perfect for machinists that need to keep their precision in check while maintaining durability.

Threading Inserts: Tiny Tools, Big Impact

It could appear that making threads is only a small part of the process, however, it’s actually an essential one. A thread that’s not properly made can ruin the part that is otherwise excellent. It’s essential to select threading inserts of the highest quality. These small, interchangeable tools are made to cut threads either on the side or inside the nut, with precision and reproducibility.

Threading inserts, as opposed to traditional taps and dies which wear out in a variety of ways provide consistent results. If one edge becomes dull it is easy to index to the next cutting edge without the need to take out the tool, or even regrind. It’s quick, clean and economical. Machinists love threading inserts because of their speed but also for their reliability. With the correct insert you are assured that your threads will fit right the first time. No second passes, no rework, and no worries about the possibility of part rejection.

The Bottom Line

Modern machining is highly time-sensitive. It’s not a good idea to waste time. So, today’s top-performing companies are focusing on smarter, more adaptable solutions for tooling. These cutting tools are not only more precise, they also simplify workflows and make it easier to change the workflow, as well as extend the useful life of the equipment. The result? There is less time spent on troubleshooting, and more time focused on providing high-quality parts. In a world of tighter margins and higher demand are commonplace and tools that operate more efficiently can give companies a competitive edge.